Inicio / Cafergot

"Buy cafergot 100mg fast delivery, back pain treatment nerve block".

By: H. Frillock, M.A., M.D., Ph.D.

Program Director, Homer G. Phillips College of Osteopathic Medicine

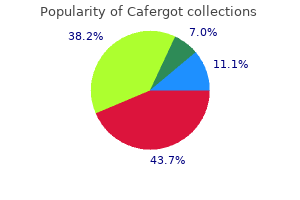

When cations (C+) are passed through the column pain treatment center of franklin tennessee buy cafergot cheap, Na+ in the resin 604 Textbook of Biochemistry; Section G: Advanced Biochemistry heel pain treatment yahoo 100mg cafergot with amex. Ion-exchange chromatography; A = negatively charged molecules attach with the beads and so move slowly; B= positively charged molecules repel with the beads pain treatment methods generic 100 mg cafergot visa, so move faster in the column no radioactivity in the supernatant wrist pain treatment exercises buy cafergot online. In B, equal quantity of unlabelled hormone is added, when labelled and unlabelled antigen molecules compete for the antibody. The displacement of labelled antigen is proportional to the unlabelled antigen in the system (Table 54. A series of test tubes are taken, in which constant quantity of antibody, constant quantity of labelled antigen and different but known quantities of unlabelled antigen are added. After a few hours of incubation, a precipitating agent is added, when antigenantibody complex, being high molecular is replaced by C+; thus C+ particles are adhered in the column, while negatively charged particles are eluted out easily. Affinity Chromatography the technique is based on the high affinity of specific proteins for specific chemical groups. Conversely, antibodies can be purified by passing through a column containing the antigen. The specificity of antibody and the sensitivity of radioactivity are combined in this technique. A constant amount of isotopelabelled hormone, constant amount of antibody and variable quantities of unlabelled hormone are taken in different tubes (see Table 54. In tube A, the labelled hormone molecules are combined with the antibody molecule; so there is. Affinity chromatography Chapter 54; General Techniques for Separation, Purification and Quantitation 605 Table 54. The radioactivity in the precipitate is inversely related to the unlabelled antigen added. The values of the radioactivity in the precipitate (last column) are shown as a graph in Figure 54. The radioactivity in the precipitate is plotted in this graph at the Y-axis, when the corresponding value in the X-axis will give the actual quantity of hormone present in that sample. There is a competition between the unlabelled hormone (antigen) present in the biological specimens and the added labelled antigen to combine with the antibody. The more the unlabelled antigen, less of the labelled antigen will combine with the antibody. The antigen-antibody reaction is allowed to take place for a definite period of time. At the end of the incubation period, the tube will contain free and bound antigen (labelled or unlabelled), as shown in Box. Principle of Radio Immuno Assay Ag + Ag* + Ab [Ag-Ab] + [Ag*-Ab] + Ag + Ag* (bound (free radioradioactivity) activity). A series of standard tubes containing known but varying concentration of the pure antigen are taken along with the unknown biological specimen. The level of the hormone in the specimen can be obtained from a calibration curve prepared from the measured radioactivity of the known standards. The radioisotope commonly used for labelling the antigen is 125I (radioactive iodine). Half life of 125I isotope is about 60 days; iodinated antigen should be used within a few months. This test is commonly employed to detect antigens or antibodies present in very small quantities in tissues or blood. Then color reagent, containing hydrogen peroxide and diamino benzidine (as described below, under antigen detection) is poured over. Therefore from the color intensity, the concentration of the antibody can be calculated. Color of filter and color of solution are complementary Color of filter Wavelength Violet Blue Green Yellow Red 420 470 520 580 680 Color of solution Brown Yellowish brown Pink Purple Green/blue. Immunofluorescennce By this time, antigen (T4 in this example) present in the serum is fixed on the antibody. Therefore intensity of the color may be measured, from which the concentration of the antigen is calculated.

The atoms C2 and N3 are derived from carbamoyl phosphate and the rest are from aspartate heel pain treatment webmd buy generic cafergot from india. Step 3: Formation of Pyrimidine Ring the 3rd nitrogen and 4th carbon are joined by a covalent bond and carbamoyl aspartate is cyclised pacific pain treatment center purchase cafergot now. Step 4: Oxidation Hydrogen atoms are removed from C5 and C6 positions phantom limb pain treatment guidelines discount cafergot 100mg without prescription, so that orotic acid is produced (step 4 pain diagnostics and treatment center dallas buy generic cafergot 100 mg line. Synthesis of pyrimidine nucleotides Chapter 39; Nucleotides: Chemistry and Metabolism 467 ii. Combined Regulation of Purine and Pyrimidine Synthesis Purine and pyrimidines are synthesized in equimolecular quantities. Orotic aciduria may also occur in ornithine transcarbamoylase deficiency (urea cycle enzyme) as carbamoyl phosphate accumulates due to defective conversion to citrulline. Allopurinol competes with orotic acid for the enzyme orotate phosphoribosyl transferase (enzyme no. Cytosine arabinoside where ribose is replaced by arabinose is another anticancer agent. Degradation of Pyrimidine Nucleotides Uracil and thymine are degraded by analogous reactions. In 1931, Barbara McClintock showed the rearrangement of genes or mobile genes in chromosomes in corn (Nobel prize, 1983). George Beadle, working with mutant strains of Neurospora suggested "one enzyme one gene" hypothesis in 1941 (Nobel prize, 1958). In this particular example, the thymidine is attached to cytidine and then cytidine to adenosine through phospho-diester linkages. The diameter or width of the helix is 2 nanometers specific sequence of bases; if the base is altered, the information is also altered. The deoxyribose and phosphodiester linkages are the same in all the repeating nucleotides. The sugar and phosphate groups comprise the handrail and the bases jutting inside represent the steps of the. The bases are located perpendicular to the helix axis, whereas the sugars are nearly at right angles to the axis. So, the adenine of one strand will pair with thymine of the opposite strand, while guanine will pair with cytosine. There are two hydrogen bonds between A and T while there are three hydrogen bonds between C and G. This is similar to a road divided into two, each half carrying traffic in the opposite direction. Tm or melting temperature is the temperature when half of the helical structure is denatured. At lower temperature, the melted strands are re-associated; this is called annealing. Acetylation of histones leads to activation of transcription, whereas de-acetylation causes depression of transcription. Sometimes histones are fixed to small ubiquitin related modifier (abbreviated as Sumo), and the process is called sumoylation. This super-twisted helix forms a spherical particle of 10 nm diameter; called nucleosome. Histones They are proteins containing unusually higher concentration of basic amino acids. About 6 such fibrils are further supercoiled to form 30 nm diameter chromatin fibers or chromatin threads. In interphase chromosomes, chromatin fibers condense to 100,000 bp loops, anchored in some supporting matrix (nuclear matrix). Chromosomes these fibers are further supercoiled and condensed to form chromosomes during the M phase of cell cycle. Depending on the length of the chromosome and the position of the centromere, the chromosomes are numbered. This region is called kinetochore, which provides the anchor for the mitotic spindle. These regions are supposed to be the site where transcription factor proteins are assembled, and where transcription is initiated.

The majority mandates technical rules for how chemical compositions must be claimed which I reject pain treatment center of baton rouge cheap 100mg cafergot. Claim 1 is directed to "a lubricating oil composition" comprising: (a) a major amount of lubricating oil; (b) a specified amount of dispersant (either about 1-10 wt pain management with shingles buy cafergot 100mg with visa. Claim 61 claims a "lubricating oil concentrate composition" comprising the same five ingredients in different advanced pain treatment center chicago order generic cafergot on line, specified amounts pain medication for senior dogs order 100mg cafergot with visa. Salomon testified that "it is easier from a manufacturing point of view to manufacture it in the ashless form. It maintains that, regardless of what ingredients are mixed together, there is infringement only if the final lubricant composition contains the five claimed ingredients, in the claimed amounts. Thus, although it is essentially uncontested that Lubrizol adds ashless dispersant and the other claimed ingredients in the claimed amounts to its motor oil, Lubrizol argues that there is no infringement because it was not proved that "ashless" dispersant, in the claimed amount, was present in its final products. Specifically, it urges, the ashless dispersant that it uses in admixture with the other ingredients specified in the claims complexes with metal moieties from those ingredients so that the dispersant in the final product can no longer be considered "ashless. The majority opinion interprets the claims somewhere between the interpretations of Exxon and Lubrizol, as covering any mixed product-final or otherwise-in which the five ingredients specified in the claims exist in the claimed amounts. And, the majority concludes, Exxon has not introduced enough evidence in the record to meet that burden. Claim Interpretation In General To determine the meaning of claims, we must examine the patent specification, other claims, and the prosecution history. Resort to testimony of those knowledgeable in the art might also be helpful to the court inasmuch as claims are interpreted from the perspective of one of ordinary skill in the art. The Specification and Claims the patent specification discusses the invention in terms of an additive for motor oil which does not interfere with the function of other additives. The particular focus is on addition of the copper compound as an antioxidant and the amount of it that is employed. Moreover, the amounts specified in the working examples and other parts of the specification are identified as the amount of the additives, not the amounts in the final product after mixing. There is no analysis anywhere in the specification of the identity of intermediate or final "complexation" products produced by combining the ingredients specified in the claims, or of their amounts. In light of those omissions, to say that one of ordinary skill in the art would nevertheless conclude that the proportions must be measured in the pot is divorced from reality. The interpretation that the claims list starting ingredients is bolstered by comparing the many nonborated, ashless dispersants disclosed at columns 6-8 of the patent, and expressly included in the claims, with the one type of dispersant-the borated version of certain ashless dispersants-that the parties agree does not complex with the metal moieties from the other ingredients specified in the claims. Yet, it is those nonborated dispersants to which the specification and claims are primarily directed. Hence, formulating the composition as interpreted by the majority, even if within ordinary skill in the art, would require extensive experimentation not even suggested in the patent, thereby rendering the claims invalid. Prosecution History As does the specification, the prosecution history focuses on the additives as starting ingredients, not on any reaction products (and the amounts in a final or intermediate product). The answer is the combination is novel and the combination does give unexpected results. The applicants, however, argued that "one can have a solution of a dispersant complexed with an oil insoluble copper compound, or can have an oil soluble [copper] compound" (emphasis added). Specifically, it shows the claim is directed to a product with "ashless" dispersant as a starting ingredient, inasmuch as some of the claims covered formation of a complex between that dispersant and metal, a formation that would render the dispersant "non-ashless". Despite that, the majority holds applicants responsible for knowing about the formation of a complex between the five ingredients required by the claims. In effect, therefore, the majority opinion penalizes applicants for not knowing or caring about exactly how their invention works. But, "it is axiomatic that an inventor need not comprehend the scientific principles on which the practical effectiveness of his invention rests. It is certainly not necessary that he understand or be able to state the scientific principles underlying his invention, and it is immaterial whether he can stand a successful examination as to the speculative items involved. With these compositions, what happens in the engine no one really knows and it is not a consideration.

Syndromes

The problem was to introduce nitrogen into the beer in a reproducible way that could then consistently give the consumer the appropriate taste sensation pain treatment for herniated disc buy cheap cafergot 100 mg. The concept was to introduce a plastic capsule with a small hole and containing nitrogen into the can and to pressurize it during canning sciatic nerve pain treatment pregnancy order cafergot no prescription. The pressure would be released when the can was opened and the nitrogen would be forced into the beer giving the characteristic creamy head and reflux of bubble formation (Lindsay et al pain treatment dvt discount cafergot 100mg overnight delivery. Originally widgets were inserted into the can before filling but this did not allow the exclusion of oxygen and hence flavour stability was poor pain medication safe dogs purchase cafergot 100 mg fast delivery. Frequently the floating widget is used since it is less likely to trap oxygen in the can during filling. Before the development of the widget some companies used solely liquid nitrogen to promote the reflux effect. In any event oxygen ingress must be kept as low as possible during canning and nitrogen can be used as the undercover gas. Cans often proceed through a tunnel between the filler and the seamer to further prevent oxygen pick-up (Brown, 1997). Some thought that this type of beer would replace standard canned ales with carbon dioxide contents of around 2. This has not happened and many consumers returned to the more effervescent product. Kegging is about filling carbonated, pressurized, pasteurized beer into sterile containers. The collection of empty kegs from depots, bars and public houses is an important part of the overall management of keg packaging (Chapter 22). The major differences concern the handling and cleaning of the much bigger container and the sterilization of the beer. These kegs are lighter than stainless steel kegs and were originally more popular. However aluminium kegs are more frequently stolen than stainless steel kegs because of the ease with which aluminium can be melted down and sold. Aluminium kegs cannot be cleaned with caustic alkali-based detergents because hydrogen gas is formed. Stainless steel kegs can be cleaned with acid or alkaline detergents and generally are more robust in use, a property that is particularly important as the container ages. All kegs have a neck containing a threaded bush (Barnes neck) into which fits a keg valve fitting. This fitting is called the spear or extractor tube and through it the filling, emptying, cleaning and automatic closing of the keg is achieved. They allow the partial dispense of the product and they operate as closed vessels with in-built leakage detection. Keg extractors should not be withdrawn outside the brewery and kegs are returned containing excess gas pressure, which prevents contamination entering. On modern keg filling lines there is a pressure test to demonstrate internal pressure and any kegs not having such a pressure will be rejected and not filled. Kegs are delivered with the extractor installed and protected from dirt during delivery with a plastic keg cap. To dispense the beer a bayonet-type dispense head is clamped onto the extractor at the bar. This allows the ingress of the top pressure gas and the outlet of the beer to the dispense tap (Chapter 23). There are several types of fitting which means that kegs from different brewers are often not interchangeable on the dispense equipment in the bar. It is now an integral part of the filling operation to test for extractor tightness as well as internal pressure in the keg before filling. Nearly all beer for kegging is bulk (flash) pasteurized in a continuous flow pasteurizer at high pressure, say 10 bar (150 lb. Flash pasteurization Flash pasteurization is carried out in a plate heat exchanger in which there are four sections. Beer is pumped to the regeneration section where it flows counter-current to hot beer and is therefore pre-heated.

Order 100mg cafergot with visa. Low back injury after deadlift | low back pain from deadlifts.

Si quieres mantenerte informado de todos nuestros servicios, puedes comunicarte con nosotros y recibirás información actualizada a tu correo electrónico.

Cualquier uso de este sitio constituye su acuerdo con los términos y condiciones y política de privacidad para los que hay enlaces abajo.

Copyright 2019 • E.S.E Hospital Regional Norte • Todos los Derechos Reservados